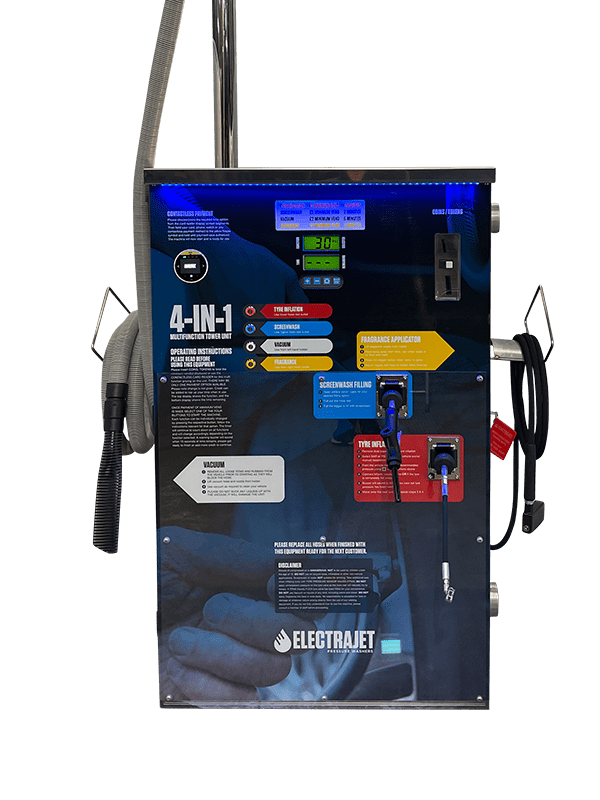

Commercial range

Electric Static

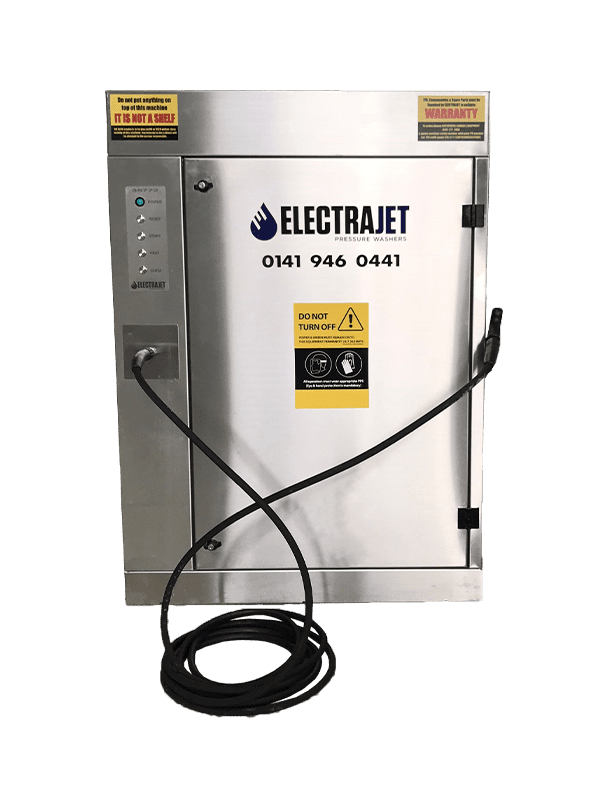

ELECTRAJET – where the name derives from and our inspiration to produce and supply specialist equipment in all fields of the pressure washing world. Environmentally friendly, hot water producing fully electric economical high pressure cleaning equipment highly effective in all environments is an understatement. Our static units have been in the market for over 30 years, and we pride ourselves in this field producing equipment that is proven for their extreme reliability in the harshest of environments. Continually evolving technology with the finest and most robust of parts available, give the customer the extreme reliance they depend on. Our high demand main dealer and contract valet customers, with their huge vehicle throughputs have voiced their compliments in our testimonials section along with many others.

- Robust stainless-steel 2-point lockable cabinet

- Durable 316 brushed stainless steel switch panel IP68

- Word renowned high pressure Cat pump

- High pressure chemical output with variable control

- RCD safety system, PLC controlled computer system

- Total frost protection available with auto blow down

All static cabinets have two-point locking systems with interlocking hinged lids. They are acoustically foam insulated providing additional protection against the elements and surrounding areas for operational noise. Official tests confirm they have neutral to no impact on surrounding noise levels, making these units suitable for the most built up or close residential area placement. Fitted standard with internal frost protection heating and feed line protection, they are suited for all environments. This equipment is fitted with WRAS approved valves, components which complies with backflow prevention laws and have water storage tanks manufactured with type AB air gaps, overflows and weirs.

Our static units can be built with various features to suit any customer and operator’s requirement. If there is a need for something not listed, please enquire and we will be happy to accommodate and customise a unit to meet your specification. We produce these units in 316 brushed stainless-steel finish or 304 grade mill-finish stainless steel, which are then powder coated to give their robust build, finish and appearance.

We offer a large inbuilt chemical storage tank, combined with being fully electric gives you an all-in-one secure wash system. Eliminating issues such as fuel and chemical storage, handling and theft from site with the added benefit of no user down time, having to refuel. The Night Time Security function locks off the control panel, set timings requested by the site will stop any unauthorised use of the equipment, giving the owner, operators complete piece of mind. These features provide additional health and safety benefits

Custom Vinyl graphics to suit your business branding are available, this can be supplied by the customer or drawn up by our design team and applied to your equipment**

Our Static Range consists of:

Hot Static All Electric Stainless-Steel Pressure Washers Units

Hot Static All Electric Utility Stainless Powder Coated Pressure Washers Units

Hot Static Diesel Heated Stainless-Steel Pressure Washers Units

Hot Static Diesel Heated Utility Stainless Powder Coated Pressure Washers Units

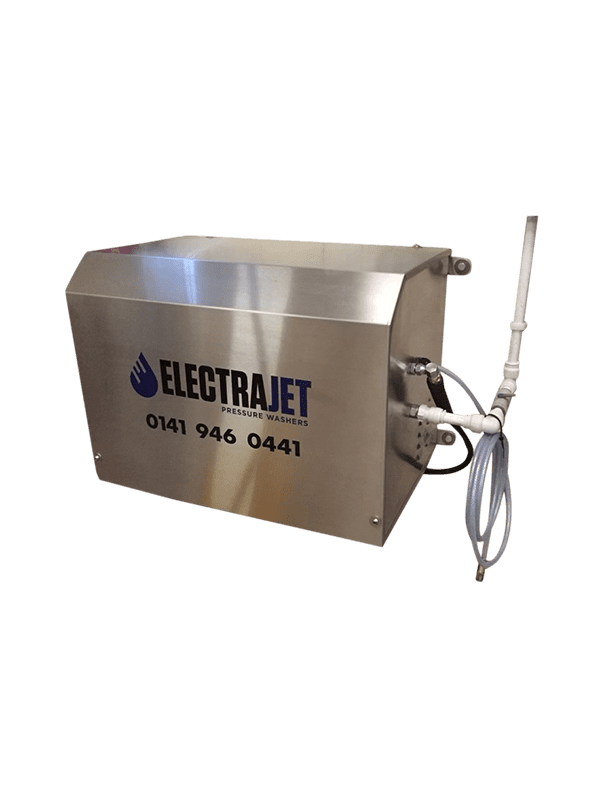

Plant Room & Bench Build Installations

Wash Bay Overhead Boom & External Control Installations

Plantroom Installations

Complete plant room installations are available with overhead swinging booms arms and external controls. These configurations are popular in large car auction and motor dealership sites where they have spacious sites for purpose-built plant rooms to house the machinery. High-pressure pipework or hoses and cabling are run out via stainless steel trays to the external wash bays areas. These units are controlled generally by pillar-mounted simple robust external control panels, making for extremely easy operation. Staff can be regularly relocated to other sites, so only basic training is required to operate.

For continual use throughout the year, compressed air blowdown systems are fitted to this type of build, ensuring in the winter months and minus temperatures the operation is ready for use at the start and throughout each day. All units are built with quick screw connections allowing easy removal and storage of the high-pressure hose and trigger gun assembly.

In certain environments mainly food manufacture, high temperature water above 65 degrees and fully stainless-steel equipment is a requirement. Our 36kw high temp unit is perfectly suited for this type of businesses, with the added benefit of the LC –Legionella Control function & CBD –Compressed air Blown Down, you can ensure and eliminate any risk to the waterstorage system or lying water in pipe work, outlet hoses, trigger gun and lance assemblies, ensuring operator and hygiene safety.

Our Static Electric Standard Operational features:

TFP/FLP - Total Frost Protection

This feature protects all internal parts from frost and leaves them to operate in temperatures as low as -15°C also incorporates a very clever feature, FLP

TFP/FLP - Total Frost Protection

TFP. This feature protects all internal parts from frost and leaves them to operate in temperatures as low as -15°C also incorporates a very clever feature, FLP

FLP - Feed Line Protection

FLP stops your mains water feed pipe to the machine from freezing allowing you to use the equipment in the worst winter weather conditions

NTS – Night Time Security

NTS allows the user to decide what time of the day operators can use the equipment with timed controls that stop the control panel on the front of the machine from being operated outside of the selected hours

ATS – Auto Timeout Stop

ATS turns the machine off after a set period of no use time to give longevity to the consumable items within the machines, for example high pressure pump seals among other parts

LPD - Leak Pulse Detect

LPD will turn off your machine when there is a leak in the system, bad enough to allow the machine to run on beyond its normal ATS setting

LC - Legionella Control

The unit will carry out a full disinfection process, this feature disinfects the hot water storage tank to prevent Legionella disease becoming present in water tank integrity and auxiliary fittings should there be a mechanical fault

TFP/FLP - Total Frost Protection

This feature protects all internal parts from frost and leaves them to operate in temperatures as low as -15°C also incorporates a very clever feature, FLP

OTCS – Over Temp Control system

RF – Real Flow

RF monitors the flow of liquid through the high-pressure pump and controls if the machine is to stop from ATS function

SM - Sleep Mode

SM shuts down all the power consuming items in the machine if there has been no use for an hour. This timing is adjustable to minimise power consumption

WM - Wake Mode

WM will awake the machine at a set time in the morning prior to the operators using it which will ensure the machine is at the correct working temperature and all systems are ready for use

WW - Water Warning

WW alerts the user that the mains water supply to the equipment has been turned off and has been for thirty minutes or more

Electric Static Model Specification

All electric units are available in three phase only and can be custom made to any customers requirements.

*Minimum quantities are required for this service

**Additional cost for this service, quantity dependant.

key

features

Robust stainless-steel cabinet

2-point lockable cabinet

Durable stainless steel switch panel

Word renowned Cat Pump

High pressure chemical output

Variable chemical control

High pressure standard rinse

RCD safety system

Plc controlled computer system

Total frost protection

Feed line protection

Water warning

Real flow control

Leak pulse detection

Legionella control

Over temp control system

Night time security

Optional

features

CBD – Compressed air Blown Down–Air compressor fitted which blows water from lines leaving them free of liquid. Especially useful on hard piped and wash bay applications where removing the hoses at night is not an option

RC – Remote Control – If it is not possible to reach the machines control panel when working in certain environments

POS – Point Of Sale – If the user requires payment before the machine can be operated. This is in the form of a contactless card reading device which accepts, cards, mobile phone and watch payments etc. Can be configured to take pre- paid fobs, if you have accounts, fobs can be issued to operators with pre- loaded credit that can be assigned to vehicles, groups or only one machine to limit any misuse. Reports can be downloaded or viewed via online portal

Twin pump

150L Inbuilt chemical storage tank

Waxing pump

Short reach easy handle high pressure lance

Extended long reach high pressure lance

Quick release trigger gun and spigots

Bespoke custom branding

Energy saving flood light

Brush and lance pole attachment

Foaming attachments & injectors

technical

specifications

Specification shown for 150 bar 13L/min 18Kw model

Voltage: 415v Three Phase

Operating Pressure: 150 bar (415v)

Output Temperature: 30 – 55°C Variable

Operating Temperature: -20°C to 70°C

Water Output: 780 LPH

Water Tank Capacity: 105L – 40 Cold with type AB air gap and weir /65 Hot

Heating Capacity: 18kw (415v)

Chemical Output:: 0-0.6 LPH

Inbuilt Chemical Tank Capacity: 150 litres

Machine Dry Weight: 180 kg

High Pressure Hose: 10m (standard)

High Pressure Nozzle Size: 1505

Installation Specification: See our downloads section

Payment

Options

Extended Warranties

Machine Hire Contracts

All Inclusive Rental Packages

Scheduled Maintenance

Purchase Options

We offer a range of rental and purchase options.

Capital Purchase

All equipment purchased outright is inclusive of the following:

- Delivery and installation on site *

- 12 months parts and labour warranty

- Optional extended warranties

- National Next day call-out

- Free chemical starter pack

* To a prepared site from our specification sheets, in downloads section

Rental Agreement

All equipment under a rental contract is inclusive of the following, relevant to the contract length:

- Delivery and installation on site *

- Full service, breakdown, and maintenance plan

- National next day call-out

- Revenue share kept by you

- With or without chemical supply and or top-up

* To a prepared site from our specification sheets in downloads section

Revenue Share

All equipment under a revenue share contract is inclusive of the following, relevant to the contract length:

- Delivery and installation on site *

- Full service, breakdown, and maintenance plan

- National next day call-out

- Revenue share kept by you

- Chemical supply and or top-up

* To a prepared site from our specification sheets in downloads section

For products with a coin mechanism, the coin count will be monitored via a monthly visit or via a web portal, dependent on the product.